The supply chain needs to be quick and efficient in a world where end customers may purchase goods from anywhere and have them delivered to their doorstep in a matter of days thanks to globalization. The effectiveness of the supply chain is determined at each stage via the warehouse management system. There shouldn’t be any issues satisfying end customers’ demand for inventory if various supply chain components effectively handle incoming and exiting inventory.

However, managing inventories is no longer a job best done on paper or with haphazard spreadsheets. The latest technological innovation named “Inventory Management”

Here, “software” steals the show thanks to its amazing powers to manage massive inventories at manufacturing facilities, retail locations, warehouses, and other locations.

What is Inventory Management Systems for Small Business – Why is it Important?

A software program called an inventory management system keeps track of every action that takes place in a warehouse or location that targets inventories. It assists in ensuring thorough tracking of sales, deliveries, and inventory orders across several vendors.

Additionally, it aids in tracking the commodities unit and enters data into the system. In these tech-savvy times, not implementing inventory management system software results in dissatisfied customers, which lowers sales and piles up the stock. Software for inventory management systems will therefore assist you in averting these circumstances.

Inventory management software improves the legitimacy of commodity tracking and instantly provides information for any type of facility, including warehouses, retail stores, depots, production hubs, and more. As a result, the automated inventory tracking system assists in monitoring the expiration dates of the products and enables prompt and informed decision-making.

Surely you’re wondering, what makes inventory management system software so crucial? Your response is in the following section.

Why is Inventory Management Systems Important?

Therefore, an inventory management system is necessary for any firm that handles or needs stock to track and manage it accurately. You’ll be working solely temporarily without this method, inevitably leading to instances where your goods are either overstocked or understocked.

Product orders, sales, delivery, and inventory levels are all tracked by an inventory management program that operates in the background. Without a reliable system for keeping an eye on these factors, you risk incurring enormous losses from excess inventory piling up, depleting your highest objectives, or having insufficient stock to satisfy client demand.

Although inventory management system software is necessary for your organization, the choice of which one to choose is yours. A range of systems are available for selection, including software for logistics and transportation, retail, warehouse, and other management applications. These systems can provide everything from basic solutions to complex ones, depending on your needs.

What are the Types of Inventory Management System Software?

Inventory management systems used to involve spreadsheets or paper files that managers had to update by hand. Thankfully, people chose the route of sustainability and new technologies, which prompted the development of software for inventory management systems. With a variety of inventory management system options, organizations may now effortlessly automate the majority of their inventory management processes.

The three categories of inventory management systems are as follows:

Perpetual Inventory Systems

Real-time inventory tracking is made easier with a perpetual inventory system. It resembles an automated system for tracking inventories. A commodity’s bar code is scanned upon sale, and it is then erased from the inventory database. In the same manner, a new good or product is scanned and added to an inventory as it is received. Furthermore, the central database and stock information are then accessible to all system components.

Periodic Inventory Systems

Physical inventory counts are used by periodic inventory systems at pre-arranged intervals to update inventory. Therefore, until the physical inventory count is finished, businesses that employ periodic inventory systems won’t know how many products or things they maintain.

Manual Inventory Systems

Using a manual inventory system is a more traditional approach to inventory management. Pen and paper or even a spreadsheet are essentially the foundation of manual inventory systems. If your company’s monthly sales are in the single digits, this might be a sensible alternative, but it’s not a viable or long-term solution for growing companies. Big retailers or vendors will require a more advanced and reliable option.

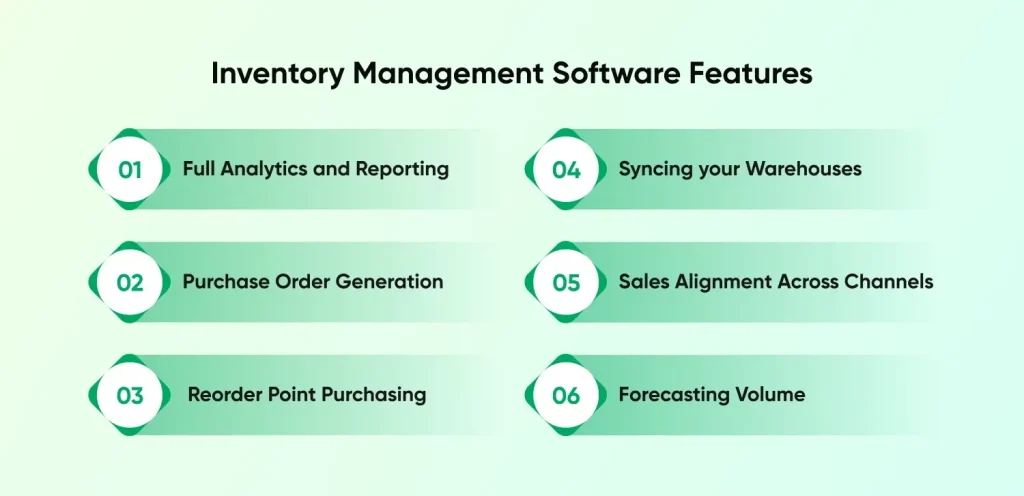

Inventory Management Software Features

One of the greatest features of inventory management software is an effective inventory control system, which increases storage capacity and properly allots various financial resources to your stock.

1. Full Analytics and Reporting

The products and goods with the greatest and lowest turnover rates are highlighted through comprehensive tool analytics and reporting. Future stock reorders are impacted (mostly helped) by these significant data-driven insights.

2. Purchase Order Generation

Purchase orders detailing the items needed are automatically created by an inventory management system (IMS) and sent to vendors.

3. Reorder Point Purchasing

Another crucial component of inventory management software is reorder point purchasing. To avoid running out of stock or becoming overstocked, it alerts firms to replenish inventory. It mainly facilitates the purchase of a predetermined quantity of inventory.

4. Syncing your Warehouses

Managers may quickly synchronize inventory data throughout the warehouses of various shops and make sure that stock levels are acceptable everywhere by utilizing the many functions of warehouse software.

5. Sales Alignment Across Channels

There is no need to predict stock locations because inventory management system software helps to coordinate inventory data entries across various sales channels.

6. Forecasting Volume

The inventory management system (IMS) can create appropriate projections and forecasts based on all the historical data available.

How to Make Inventory Management System – 7 Simple Steps

The development process of inventory management software has a significant impact on its effectiveness. The following are the main stages of developing software for inventory management:

1. Recognise the Prerequisites

Before anything else, it’s important to define exactly what you need from the inventory management software. Every organization has different demands and requirements, as we explained in the previous section, and inventory management systems are made to accommodate these differences. Recognize whether software alone or barcode/RFID support is planned. In addition, if ERP, CRM, accounting system integration, etc., is required.

2. Planning Projects

Create a project outline to help you reach the important checkpoints along the way. All of the information about the project’s goals, objectives, KPIs, mitigation strategies, and anticipated results should be included in the project plan. This phase also covers planning for the inventory management trends and technologies that will be employed in the project, cost analysis and breakdown, and anticipated project timeline.

3. Development of Inventory Systems

The project’s fundamental development takes place at this phase. Hiring a software development partner who can handle all of the coding and technical work required to build the software is necessary for the same. A prototype will be created by the development partner and submitted for approval.

The development team continues working on the software’s backend by coding it after the relevant stakeholders have approved the prototype. After developing the software, the quality analysis team checks it multiple times to make sure that it is error-free and performs to its fullest potential.

4. Third Party Integration

The usefulness of inventory management software is further improved by third-party integration. It is possible to combine new fleet management software development with an existing warehouse system, application, ERP, CRM, accounting system, or anything else that is currently in use. A warehouse owner can accomplish many jobs more easily by integrating this software, as it eliminates the need to transfer large amounts of data between locations.

5. Software Deployment

The program can now be installed at the store or warehouse. Software configuration will be done first to guarantee the backup and data recovery process. Once these conditions are satisfy, the software is put into use for the company’s actual testing procedures.

The program is installed in the system for ongoing operation when it has produced the desired results and performance. This will be well taken care of by the custom software development company which is an expert in creating a robust inventory management system.

6. User Training

The necessary parties need to be aware of the software once it has been implement in the system. To accomplish this, the corresponding software users receive training on how to operate the new system and promptly update the new data. It guarantees that the company is making the most of the software’s capabilities.

7. Post-launch Assistance and Maintenance

The software will require maintenance and post-maintenance assistance in addition to deployment. It is necessary to notify the relevant development team for enhancements if users report bugs or if a function is not functioning as intended.

Conclusion

Businesses can effectively track, arrange, and manage their commodities and raw materials-which are necessary to successfully deliver items to customers-with the use of inventory management software. For managing their warehouse needs, businesses are increasingly employing this software, either as a standalone module or as a dedicated section of Enterprise Resource Management software. Thus, this is the perfect moment to include this in your company’s operations if you haven’t already. Get in touch with CMRAIX – an inventory management software development company right now if you’re interested in developing an inventory management app as well. We are the top provider of rich logistics software development services for -warehouse inventory management systems.

Frequently Asked Questions

How to Create an Inventory System?

Required steps for creating an inventory management system

Design an inventory system and engineer the requirements.

Give the project a thorough plan.

QA is conducted and inventory software is developed.

Connect the software to other platforms.

Install the system for inventory.

Provide training to users.

Assure post-launch assistance.

What Is the Cost of Building an Inventory Management System?

The price to create an inventory management system may range from $60,000 to $100,000 USD, according to CMARIX’s industry expertise. The price of inventory management software is influenced by a few things. After you comprehend these elements, the software development team will be able to present you with a pricing estimate.

What Is Inventory Management Software?

It is a technology gadget that, as its name implies, tracks every movement of inventory within a warehouse or other location that targets inventory. It guarantees thorough tracking of sales, orders, delivery, and inventory levels among the various partners, ensuring that every commodity unit is traceable and inputted into the system.

What Is the Most Common Inventory Management System?

Top inventory management solutions

Katana is a platform for cloud inventories.

Ordoro: Inventory management for e-commerce.

Restaurant inventory software from Upserve.

The software for managing inventories is called Zoho Inventories.

POS system from Square.